In today’s energy-reliant world, inverter batteries stand as pillars for both residential and commercial power systems, providing critical backup during outages and ensuring uninterrupted power supply. Proper inverter battery maintenance not only extends their lifespan but also enhances their efficiency and reliability.

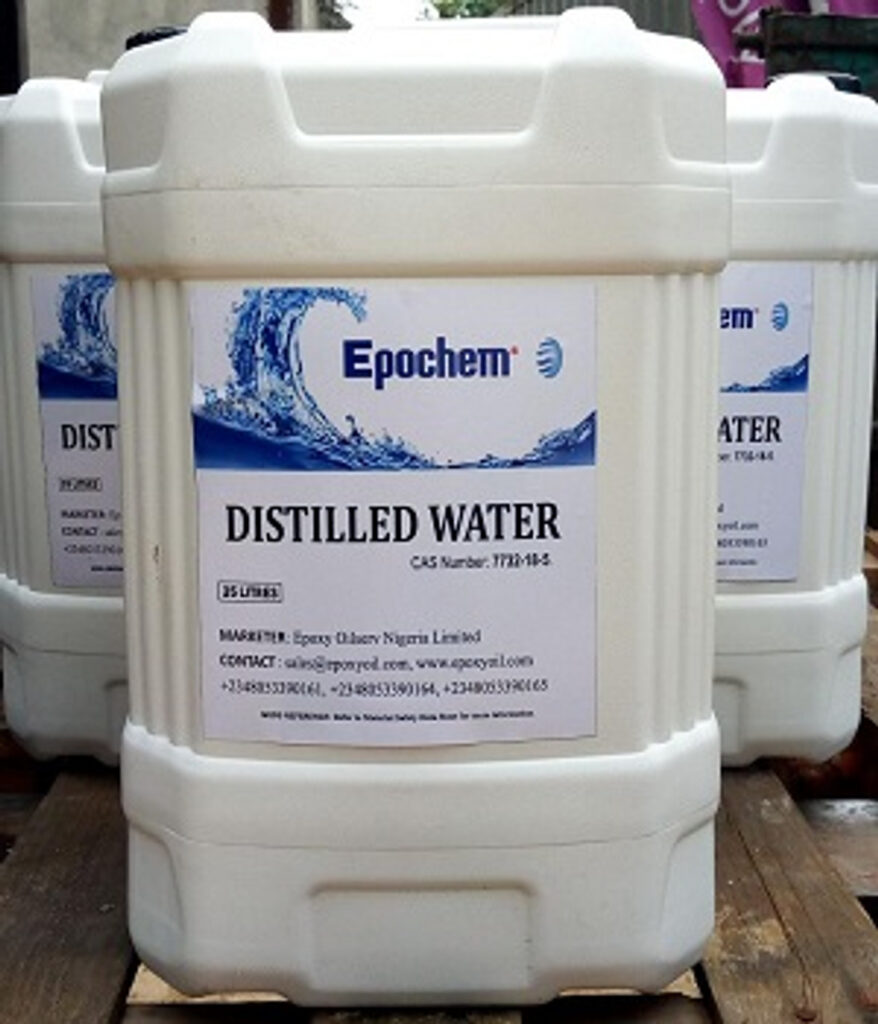

One of the best practices for maintaining an inverter battery is to regularly top up the battery with distilled water, which is crucial for preserving the health and efficiency of the battery. Distilled water is free from impurities and minerals that are commonly found in tap water and can lead to the buildup of deposits on the battery’s lead plates. These deposits can significantly reduce battery capacity and shorten its overall lifespan by impeding the electrochemical reactions necessary for power generation. By using distilled water, you ensure that the electrolyte level within the battery remains optimal, preventing over-concentration of acid and avoiding the risk of battery plate exposure, which can cause irreversible damage. Regular monitoring and maintenance of water levels with distilled water not only extend the operational life of the battery but also maintain its charging capacity, ensuring that your power backup system remains reliable in times of need.

This guide aims to equip you with comprehensive knowledge and practical tips to maintain your inverter battery optimally.

Understanding Inverter Batteries

Types of Inverter Batteries:

- Lead-Acid Batteries: Traditional choice, known for their cost-effectiveness and wide availability. Require regular maintenance, including water topping and terminal cleaning.

- Gel Batteries: Use gelified electrolyte, offering better cycle life and minimal fume release, making them safer and more maintenance-free than lead-acid batteries.

- Absorbed Glass Mat (AGM) Batteries: Feature fiberglass matting between battery plates which contain the electrolyte. AGM batteries are more efficient than gel and lead-acid batteries, providing better power consistency and requiring less upkeep.

How They Work:

- Inverter batteries store electrical energy as chemical energy during times of power availability. During a power outage, they convert this chemical energy back to electrical energy to power connected devices. The efficiency of this process depends significantly on the health and maintenance of the battery.

Setting Up Your Inverter Battery System

Initial Installation:

- Ensure that the battery is installed in a well-ventilated area to prevent overheating.

- Set up the battery on a non-conductive and level surface to avoid any potential short circuits and ensure even charge distribution.

Safety Precautions:

- Always wear protective gear when handling batteries, especially gloves and goggles.

- Keep open flames or sparks away from the battery to prevent accidental explosions from hydrogen gas that is typically released by lead-acid batteries.

Regular Inverter Battery Maintenance Procedures

Visual Inspections:

- Regularly inspect the battery for signs of damage such as cracks, bulging, or leaks. Any of these conditions can signify that the battery needs professional attention.

Cleaning Techniques:

- Clean battery terminals periodically with a solution of baking soda and water to remove any corrosion. Use a non-metallic brush to avoid short circuits during cleaning.

- Ensure that the area around the battery is free from debris and dust to prevent accidental covering of vent caps which can lead to overheating.

Water Levels and Topping Up:

- For lead-acid batteries, check the electrolyte level regularly. The water should just touch the bottom of the refill hole. Use only distilled water to top up the battery as tap water can introduce minerals that crystallize and damage the battery internals.

This initial segment of the guide covers the fundamental concepts and initial maintenance steps critical for ensuring the optimal performance and longevity of inverter batteries. Upcoming sections will delve deeper into the best practices for charging, the technology behind battery testing and monitoring, and troubleshooting common issues that may arise during the battery’s operational lifecycle.

Charging Practices for Inverter battery maintenance

Charging Guidelines:

- Regular Charging: It’s essential to charge the inverter battery regularly to maintain its health. Avoid allowing the battery to be discharged below 50% capacity as it can shorten its lifespan.

- Appropriate Charging Cycle: Implement a consistent charging cycle. Overcharging or undercharging can both degrade battery performance and life.

- Use of Correct Charger: Always use a charger that matches the battery specifications. Using an incompatible charger can lead to inefficient charging and even damage.

Understanding Charging Cycles:

- Batteries have a limited number of charging cycles before their efficiency starts to wane. Regular, complete cycles help maintain battery capacity.

- Partial charges can be beneficial in the short term but establishing a routine for full charge cycles will enhance long-term battery health.

Use of Appropriate Chargers:

- Ensure that the charger used is suitable for the type of battery (lead-acid, gel, or AGM). Incorrect charger types can increase the risk of damage due to improper voltage or current.

Testing and Monitoring to boost Inverter Battery Maintenance

Routine Testing:

- Capacity Testing: Use tools like a multimeter or a hydrometer to check the battery’s voltage and specific gravity of the electrolyte, respectively. These readings help assess the overall health and functionality of the battery.

- Load Testing: This involves applying a load to the battery and measuring its ability to sustain the nominal voltage under load conditions. Load tests help in determining the end of the battery’s functional life.

Monitoring Systems:

- Consider installing a battery monitoring system that continuously assesses the battery’s state of charge, health, and operational status. These systems can provide alerts for low battery, water level indicators for lead-acid types, and other critical information that can aid in maintenance.

Troubleshooting Common Issues in Inverter Battery Maintenance

Identifying Problems:

- Swelling or Bulging: Often caused by overcharging or heat exposure.

- Leakage: Electrolyte leaks indicate casing damage or overfilling.

- Rapid Power Loss: Usually a sign of aged batteries or those with compromised capacity due to sulfation.

Quick Fixes and When to Seek Professional Help:

- Minor Issues: Loose connections can often be tightened, and terminals cleaned to restore proper function.

- Major Issues: If the battery repeatedly fails load tests, exhibits significant swelling, or leaks, it’s time to consult a professional. These signs can indicate irreversible damage requiring battery replacement.

This section of the content builds on the basic inverter battery maintenance practices introduced earlier, advancing into more detailed aspects of battery care including charging practices, the importance of using the correct equipment, and methods for testing and monitoring inverter batteries. As we continue, the focus will shift to detailed troubleshooting techniques, enhancing battery life through advanced care strategies, and finally concluding with practical advice encapsulated in an FAQ section.

Enhancing Battery Life and Performance

Optimal Storage Conditions:

- Temperature Control: Store batteries in a cool, dry place to minimize the impact of temperature extremes, which can accelerate degradation processes such as sulfation in lead-acid batteries.

- Proper Ventilation: Ensure good air circulation around batteries to prevent the buildup of gases and heat, which can affect battery performance and safety.

Advanced Tips for Inverter Battery Maintenance:

- Equalization Charge: For lead-acid batteries, performing an equalization charge once a month helps to balance the battery cells and correct the specific gravity imbalances. This extends the battery life by preventing sulfation.

- Using Desulfators: Implementing devices like desulfators can reverse the buildup of sulfates on batteries’ lead plates, thereby enhancing their effective lifespan.

- Balancing Battery Strings: If using multiple batteries in a string, ensure they are balanced in terms of charge and health to prevent uneven wear and extend the overall battery system’s life.

Replacement and Disposal

Knowing When to Replace:

- Age Indicator: Most batteries have a lifespan of 3-5 years depending on their usage and maintenance. If your battery is approaching this age and showing signs of wear, consider replacement.

- Performance Decline: Persistent issues such as not holding a charge or significantly reduced capacity are clear indicators that a battery needs to be replaced.

Proper Disposal Methods:

- Recycling Centers: Lead-acid batteries are highly recyclable. Take the old batteries to certified recycling centers where they can be safely processed, and valuable materials can be recovered.

- Environmental Compliance: Follow local guidelines for the disposal of hazardous materials to ensure environmentally safe practices.

FAQ Section

Q1: How often should I clean my inverter battery terminals?

Clean the battery terminals every six months or whenever you notice corrosion buildup to ensure good electrical conductivity and battery health.

Q2: What is the main cause of inverter battery failure?

The most common cause is sulfation, which occurs when a battery is allowed to remain in a discharged state for an extended period.

Q3: Can I use regular tap water to top off a lead-acid inverter battery?

No, always use distilled water. Tap water contains minerals that can precipitate and damage the internal structure of the battery.

Q4: How can I ensure the longest life for my inverter battery?

Regular maintenance, proper charging, keeping the battery at room temperature, and using a desulfator can all contribute to extending your battery’s life.

Q5: Is it necessary to use a battery monitoring system?

While not necessary, a battery monitoring system can greatly aid in maintaining your battery by providing real-time data on its condition and alerting you to potential issues before they become serious.

Conclusion

Maintaining your inverter battery effectively is crucial for ensuring reliable power backup and optimizing the return on your investment in power infrastructure. By adhering to the best practices for battery maintenance outlined in this guide, you can significantly extend the life of your battery, enhance its performance, and avoid common issues that lead to battery failure.

To discover more about inverter battery maintenance or explore a range of high-quality inverter batteries, Contact us at; Epoxy Oilserv Nigeria Limited. At Epoxy, we offer expert advice, maintenance support, and all the tools you need to keep your power systems running efficiently. Upgrade your energy solutions with Epoxy Oilserv today, where power meets reliability and sustainability.