Air tools or Pneumatic tools are powered by compressed air. Common types of these air-powered you may already know about that are used in the industry include buffers, nailing and stapling guns, grinders, drills, jackhammers, chipping hammers, riveting guns, sanders, and wrenches. In a situation that does not have sufficient space and calls for portability, a pneumatic (air) tool can also be driven by carbon dioxide in a compressed seamless cylinder. This article is part of a series of maintenance tips we are gathering for the maintenance of air tools because air tools are not that cheap. We want anyone investing in air tools to enjoy them for a long time.

Air tools can also be a little pricy than cordless or electric power tools, and this is because they last far longer than other types of power tools; this is why we think that the best workshops have air-powered tools installed in them. Power tools and other heavy equipment that are powered by electricity or just cordless tools often dominate most workshops. air-powered tools are some of the most reliable components, and provide a number of benefits for any workshop, and here are the reasons why.

Benefits of air-powered workshops

Air tools are Light And Energy Efficient

Air-powered tools use compressed air to operate, unlike conventional equipment that are powered by electricity and batteries (eg cordless tools). tools powered by air are almost always more energy efficient, helping workshop owners from spending extra money on batteries and other voltage supply.

Because they don’t have huge power sources, they are significantly lighter than their electrical counterparts, making them more portable and easy to use. It also means that your workshop is free from electric cables, which can be both an annoyance and electric-shock hazard.

They Can Be Stalled Indefinitely

Electric tools or cordless can burn out if stalled over a long period of time. In addition, the back Electro Magnetic Force drops to zero when this happens, overheating the motor. Air tools don’t have this problem of stalling over a long time, without electrical motors, they are spark-less, which makes them ideal for use in hazardous environments.

Air tools are Lightweight, and Simple in Design

Since each air tool doesn’t have a motor of its own ( the power from the air compressor gives it its power), air tools are significantly lighter in weight than their electric counterparts. This is especially advantageous for those who use tools for a long period of time. Pneumatic sanders, grinders, spray guns and sand blasters are just a few of the tools that are run continuously in a variety of environments.

Without the extra bulk of a motor, you will experience less muscle fatigue and have better control over the operation of the tool, even after a long day. You will also get the benefit of an ergonomically-focused design that will be better to grip and pivot during use, and the smaller size makes it easier to complete a range of specific applications.

All pneumatic tools also boast a much simpler design than electric tools, which results in less breakdown, easier repair and a longer life. Whether you’re using air tools in your home shop or you have hundreds of tools operating in a production line, this is a huge benefit when you’re considering the long-term costs of tools. Other qualities that relate to the lightweight, simple design of air tools are:

- Easy to hook up

- Very low occurrence of malfunctioning (no overheating, short circuiting or risk of electrocution)

- Quick user training

- Easy to maintain since there are fewer moving parts

Has Lower Costs of use

There are certainly circumstances when you will see lower energy costs with electric tools, especially with irregular use for low power operations, like using a brad gun or drill. However, when tools are used continuously, air powered tools are the most cost-effective in the majority of situations.

You will see the most savings for professional applications in both the cost of the tools and in the energy consumption. There are many ways energy costs can be controlled in an air compressor system, and it’s your best way to keep costs down.

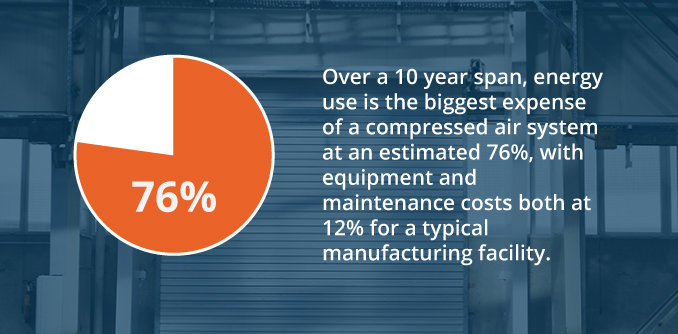

Over a 10 year span, energy use is the biggest expense of a compressed air system at an estimated 76%, with equipment and maintenance costs both at 12% for a typical manufacturing facility.

If you’re using just one or two tools in your shop on an occasional basis, you won’t benefit from the lower costs of pneumatic tools. However, the reliable power supply and low rate of tool burnout may be the benefit that is more attractive to your situation.

Putting the cost of the air compressor aside, the initial purchase of an air tool as well as the maintenance and frequency of replacement are all lower than that of the electric equivalent.

Air tools are primarily Reliable

From increased power potential to the stability of a well-maintained compressor system, air-powered tools are a reliable way to get work done. The biggest advantages of air powered tools for the industrial market is the dependability of continuous use — less breakage and maintenance mean less downtime.

Even an auto repair shop or a woodworking facility, that may not have as much urgency to keep production up as multi-million-dollar organization, will be inconvenienced and experience a loss in profits when their tools and power system let them down. When comparing air powered tools vs. electric, air tools come out on top for reliability in power supply and equipment uptime but using air tools require following all the safety protocols.

Air tools are a versatile Option for Any Environment

Air tools can easily adapt to any environment, even if there is no electricity to run an air compressor. The versatility of compressed air as a power source is unmatched by other power sources such as electricity, natural gas and the highly-flammable gasoline. Compressed air can be stored in cylinders, which may be used as the power source for air tools in places such as an oil rig or mine.

Although the air lines can be an issue for some situations, the reliability of compressed air as a power source makes pneumatic tools the ideal choice for a wide range of applications, whether by using reliable electric hook up to run a compressor or by using tanks of compressed air.

With the ability to adjust the pressure through the air compressor, you can easily switch tasks from high-powered sandblasting to low-powered cleaning with speed and ease. You’ll also be able to disconnect and reconnect your air tools quickly, allowing for more efficient practices and a higher production rate. Experts are recommending that air powered tools are best for shipbuilding because of the safety nature of the tools

Many industries need the clean and dry power of compressed air that hydraulic systems do not provide. Soiling products with oil or other contaminates is unacceptable in many industries like food, packaging, leather and textiles.

Air compressor systems also allow for higher conversion of energy into work when compared to hydraulic operations. The flow speed of compressed air can reach 20 miles per second (m/s), where hydraulic applications can’t even manage half that at 5 m/s. This benefit won’t be relevant for all uses of power tools, but for those applications where quality production can happen at higher speeds, air tools are a welcome solution with economic benefits that affect manufacturers and consumers. before making up your mind on why air tools are great please read this article Why You should use pneumatic air tools? And not cordless and electric power tools?

Contact us for your air powered tools requirements