The Ultimate Guide to Surface Refurbishment: Restoring Beauty and Functionality

Introduction

Surface refurbishment is a crucial process in modern maintenance practices, focused on restoring and enhancing the appearance, durability, and functionality of various surfaces. Whether it’s a metal pipeline, a concrete floor, or a wooden deck, surfaces are constantly exposed to environmental stressors that can lead to wear and deterioration over time. Surface refurbishment involves a range of techniques designed to address these issues, ultimately prolonging the life of the surface and improving its performance.

This practice is essential across numerous industries, including industrial manufacturing, marine, construction, and residential sectors. By refurbishing surfaces, companies and individuals can avoid costly replacements, reduce waste, and maintain the aesthetic and structural integrity of their assets.

Why Surface Refurbishment Matters

Surface refurbishment plays a vital role in maintaining both the beauty and functionality of assets. Here’s why it’s important:

- Aesthetic and Functional Impact: Over time, surfaces can lose their appeal due to factors like corrosion, cracking, and fading. Refurbishment helps restore the original look of the surface while also enhancing its functionality, whether that means providing better protection against environmental elements or improving safety features.

- Cost-Effectiveness and Sustainability: Refurbishment is often a more economical choice than replacement. It reduces the need for new materials, lowers disposal costs, and minimizes downtime. Additionally, using eco-friendly materials and techniques in refurbishment aligns with sustainable practices, helping to reduce environmental impact.

- Enhanced Lifespan and Value: Regular surface refurbishment can significantly extend the life of assets, ensuring they remain in good condition for years to come. This not only preserves the value of the asset but can also enhance its marketability, whether in an industrial, commercial, or residential context.

Types of Surfaces and Common Issues

1. Metal Surfaces

Metal surfaces are widely used in industrial, marine, and construction settings due to their strength and durability. However, they are also prone to issues like rust, corrosion, and general wear and tear. These problems can compromise the integrity of the metal, leading to potential safety hazards and reduced functionality.

- Common Issues: Rust and corrosion are the most prevalent issues affecting metal surfaces. These occur due to prolonged exposure to moisture, chemicals, and saltwater, especially in marine environments. Additionally, metal surfaces can suffer from scratches, dents, and general wear, all of which can degrade their performance over time.

- Importance of Maintenance: Regular refurbishment of metal surfaces is essential to prevent these issues from escalating. Techniques like abrasive blasting, coating, and polishing are commonly used to restore metal surfaces, ensuring they remain strong and resistant to further damage.

2. Concrete Surfaces

Concrete is a versatile and durable material commonly used in building foundations, infrastructure, flooring, and more. Despite its strength, concrete is not immune to damage and degradation over time.

- Common Issues: Cracking is a major concern with concrete surfaces, often caused by structural stress, temperature changes, or improper curing. Spalling, where the surface layer begins to flake or chip away, and discoloration are also common problems that can affect the appearance and integrity of concrete.

- Applications: Concrete surfaces are ubiquitous in both residential and commercial settings, from driveways and walkways to industrial floors and large infrastructure projects. Keeping these surfaces in good condition through refurbishment is critical to maintaining their structural integrity and aesthetic appeal.

3. Wooden Surfaces

Wood is a popular material in residential and commercial construction, valued for its natural beauty and warmth. However, wood surfaces are particularly vulnerable to environmental factors that can cause deterioration over time.

- Common Issues: Wooden surfaces can suffer from rot, warping, and fading due to exposure to moisture, UV rays, and temperature fluctuations. Without proper care, wood can become brittle, discolored, and structurally unsound.

- Importance in Spaces: Wooden surfaces are often found in decks, flooring, furniture, and exterior facades. Refurbishing wood not only restores its appearance but also protects it from future damage, ensuring it remains a durable and attractive feature in any space.

4. Composite and Specialized Surfaces

Modern construction and industrial applications often use composite materials and specialized surfaces designed to withstand specific conditions. These materials are engineered to offer superior strength, durability, and resistance to environmental factors.

- Common Issues: Despite their advanced properties, composite and specialized surfaces can still experience degradation, such as surface erosion, UV damage, and chemical exposure. Addressing these issues through refurbishment is key to preserving the intended performance and longevity of these surfaces.

- Applications: Composite materials are commonly used in areas like aerospace, automotive, and high-performance architectural projects. Specialized surfaces, such as anti-slip coatings or fire-resistant treatments, are often applied in safety-critical environments. Refurbishing these surfaces ensures they continue to meet strict performance standards.

Surface Refurbishment Techniques

1. Surface Cleaning

Cleaning is the first and most crucial step in any surface refurbishment project. It prepares the surface for subsequent treatments by removing contaminants that could interfere with adhesion, coating, or repair processes. The method chosen for cleaning depends on the type of surface and the nature of the contaminants.

- Abrasive Blasting: This technique uses a high-pressure stream of abrasive materials, such as sand, grit, or steel shot, to remove rust, old paint, and other surface contaminants. It is highly effective for cleaning metal and concrete surfaces, particularly in industrial settings.

- Chemical Cleaning: For surfaces sensitive to mechanical abrasion, chemical cleaning may be the preferred method. It involves the use of chemical agents to dissolve and remove oils, grease, dirt, and other residues. This technique is often used in applications where precision is required, such as in electronics or medical equipment refurbishment.

- Pressure Washing: This method uses high-pressure water jets to clean surfaces, effectively removing dirt, grime, and other contaminants. Pressure washing is commonly used on large concrete or wooden surfaces, such as building exteriors, decks, and driveways.

2. Surface Repair

After cleaning, the next step in surface refurbishment often involves repairing any damage to restore structural integrity and prepare the surface for protective treatments. Surface repair is critical to extending the life of the material and ensuring it functions as intended.

- Crack Filling: Cracks in surfaces like concrete and wood can lead to further deterioration if left unaddressed. Filling these cracks with appropriate materials, such as epoxy fillers or sealants, prevents water ingress, which can cause additional damage and structural weakening.

- Patching and Structural Repairs: For larger areas of damage, such as spalling in concrete or rotted sections of wood, patching is necessary. This involves removing the damaged material and replacing it with new material that matches the original in strength and appearance. In cases where the damage affects the structural integrity, reinforcement may be required, such as using rebar in concrete or adding support beams in wooden structures.

- Use of Epoxy Resins and Sealants: Epoxy resins are widely used in surface repair due to their strong adhesive properties and durability. They are particularly effective in filling gaps and bonding materials in metal and concrete surfaces. Sealants, on the other hand, are often used in joints and seams to create a watertight seal, protecting the surface from moisture and environmental factors.

3. Surface Coating and Protection

Once the surface is repaired, applying a protective coating is essential to shield it from future damage. Surface coatings not only enhance the appearance of the material but also provide a barrier against environmental stressors like moisture, chemicals, and UV radiation.

Types of Protective Coatings:

- Epoxy Coatings: Known for their durability and resistance to chemicals and abrasions, epoxy coatings are a popular choice for industrial applications, such as coating machinery, pipelines, and floors.

- Polyurethane Coatings: These coatings offer excellent resistance to wear, impact, and UV light, making them ideal for surfaces exposed to harsh conditions, such as outdoor furniture, vehicles, and marine vessels.

- Anti-Corrosion Coatings: Designed specifically for metal surfaces, anti-corrosion coatings prevent rust and oxidation, prolonging the life of the material. These are especially important in marine and industrial environments where metal surfaces are exposed to moisture and corrosive substances.

Application Techniques:

- Spraying: This is one of the most efficient methods for applying coatings, especially on large or complex surfaces. Spraying ensures even coverage and a smooth finish, which is critical in industrial settings where consistency is key.

- Brushing and Rolling: For smaller areas or surfaces requiring detailed work, brushing or rolling can be more appropriate. These techniques allow for more control over the application, making them suitable for intricate surfaces or areas where precision is required.

- Dipping: This technique involves immersing the surface or object into a vat of coating material, ensuring complete coverage. Dipping is often used for small parts or tools that need a uniform protective layer.

Surface Polishing and Finishing

The final step in the surface refurbishment process is polishing and finishing. This step enhances both the appearance and performance of the surface, giving it a smooth, refined look and improving its resistance to wear and tear.

- Polishing Techniques:

- Mechanical Polishing: This involves using abrasive tools to smooth the surface and remove any imperfections. It is commonly used on metal surfaces to achieve a glossy, mirror-like finish. In industrial settings, mechanical polishing can also reduce friction and wear, extending the life of machinery and equipment.

- Chemical Polishing: For surfaces that cannot withstand mechanical abrasion, chemical polishing offers an alternative. It uses chemical agents to remove surface imperfections at a microscopic level, resulting in a smooth, reflective surface. This method is often used in electronics and precision engineering where surface smoothness is critical.

- Finishing Options:

- Matte Finish: A matte finish provides a non-reflective surface that is both aesthetically pleasing and practical, as it hides fingerprints and smudges. This type of finish is popular in modern architecture and interior design.

- Gloss Finish: Gloss finishes offer a high-shine, reflective surface that highlights the color and texture of the material. Glossy surfaces are often used in decorative applications, such as countertops, furniture, and automotive parts.

- Textured Finish: Textured finishes add a tactile element to the surface, improving grip and reducing the risk of slipping. This is particularly important in flooring applications, especially in areas prone to moisture, such as bathrooms, kitchens, and outdoor walkways.

Innovative Techniques in Surface Refurbishment

The field of surface refurbishment is constantly evolving, with new technologies and materials being developed to improve efficiency, durability, and environmental sustainability.

- Emerging Technologies:

- Laser Cleaning: Laser cleaning is a cutting-edge technology that uses focused laser beams to remove contaminants from surfaces without damaging the underlying material. It is highly precise, making it ideal for delicate surfaces or areas requiring detailed work.

- Nano-Coatings: Nano-coatings are ultra-thin layers that provide superior protection against corrosion, UV rays, and other environmental factors. These coatings are particularly effective on metal and glass surfaces, offering long-lasting durability with minimal maintenance.

- Benefits of Innovative Methods: These emerging techniques not only improve the quality of surface refurbishment but also offer greater environmental benefits. For example, laser cleaning reduces the need for chemical solvents, and nano-coatings extend the life of surfaces, reducing the frequency of refurbishment and material waste.

Benefits of Surface Refurbishment

1. Cost-Effectiveness

One of the primary advantages of surface refurbishment is its cost-effectiveness compared to full replacement. Refurbishment often involves less labor and material costs, as it focuses on repairing and restoring existing surfaces rather than starting from scratch. This approach not only reduces expenses but also minimizes downtime, allowing businesses and homeowners to resume normal activities more quickly.

- Comparison with Replacement: Replacing entire surfaces or structures can be significantly more expensive due to the costs of new materials, installation, and potential disruption. Refurbishment provides a more economical alternative by extending the life of existing assets and addressing issues before they necessitate costly replacements.

- Long-Term Savings: Regular refurbishment can lead to long-term savings by preventing more severe damage that would require more extensive and costly repairs or replacements. Investing in timely refurbishment helps maintain the value of assets and avoids sudden, large expenditures.

2. Aesthetic Enhancement

Refurbishing surfaces can greatly enhance their appearance, restoring their original beauty and improving the overall look of a space or structure. This is particularly important for high-visibility areas, where the condition of surfaces directly affects the perception of the property or facility.

- Restoring Original Beauty: Over time, surfaces can become stained, discolored, or worn. Refurbishment techniques like cleaning, coating, and polishing can rejuvenate these surfaces, bringing them back to their original state and improving their visual appeal.

- Impact on Property Value: Well-maintained surfaces contribute to the overall value of a property. For commercial properties, a fresh, appealing appearance can attract customers and clients, while for residential properties, it can enhance curb appeal and marketability.

3. Improved Functionality and Safety

Surface refurbishment not only enhances appearance but also improves the functionality and safety of surfaces. Addressing issues like cracks, wear, and corrosion ensures that surfaces perform their intended functions effectively and safely.

- Ensuring Optimal Performance: By repairing and protecting surfaces, refurbishment helps maintain their intended performance characteristics. For example, refurbishing industrial floors can improve their load-bearing capacity, while maintaining wooden decks can prevent unsafe conditions caused by rot or splinters.

- Enhancing Safety: Surfaces that are in poor condition can pose safety hazards, such as slippery floors, structural weaknesses, or exposed sharp edges. Refurbishing these surfaces addresses such risks, ensuring a safer environment for users and reducing the likelihood of accidents or injuries.

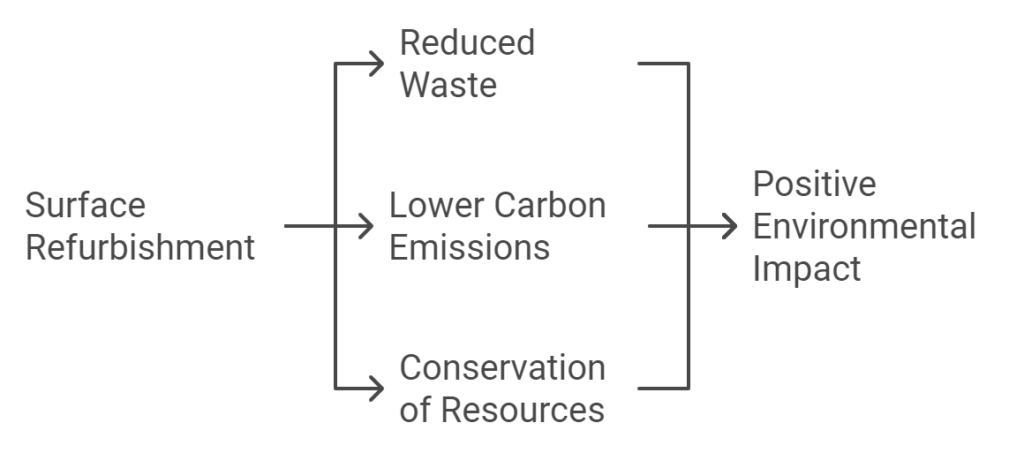

Environmental Impact of Surface refurbishment

Surface refurbishment aligns with sustainable practices by reducing waste and minimizing resource consumption. By extending the life of existing surfaces and using eco-friendly materials, refurbishment supports environmental conservation efforts.

- Reducing Waste: Refurbishing surfaces often involves repairing and reusing existing materials rather than discarding them. This approach helps reduce the amount of waste sent to landfills and lessens the demand for new raw materials.

- Eco-Friendly Materials and Methods: Many modern refurbishment techniques use environmentally friendly materials and methods, such as low-VOC coatings, water-based cleaners, and recyclable materials. These choices contribute to a lower environmental footprint and support green building practices.

Applications of Surface Refurbishment

1. Industrial and Manufacturing Facilities

Surface refurbishment is essential in industrial settings to maintain the functionality and safety of machinery, equipment, and infrastructure. Regular maintenance and refurbishment help ensure that these assets continue to operate efficiently and meet safety standards.

- Machinery and Equipment: Refurbishing surfaces on machinery and equipment, such as coating and repairing parts, prevents deterioration and extends their operational life. This helps avoid unexpected breakdowns and costly downtime.

- Pipelines and Storage Tanks: Industrial pipelines and storage tanks often face harsh conditions that can lead to corrosion and wear. Refurbishment techniques, such as anti-corrosion coatings and structural repairs, help protect these critical components and ensure their reliability.

2. Marine and Offshore Structures

The marine environment presents unique challenges for surface maintenance due to exposure to saltwater, UV rays, and physical wear. Refurbishing marine and offshore structures is crucial for preventing damage and ensuring their safe and effective operation.

- Ships and Vessels: Regular refurbishment of ship hulls and other marine surfaces helps protect against corrosion, biofouling, and physical damage. This maintenance is vital for the safe and efficient operation of vessels.

- Offshore Platforms and Docks: Offshore platforms and docking facilities are subject to extreme environmental conditions. Surface refurbishment, including coating and repair, helps maintain the structural integrity and functionality of these structures.

3. Residential and Commercial Buildings

Surface refurbishment in residential and commercial buildings improves both the aesthetics and functionality of interiors and exteriors. This includes maintaining floors, walls, facades, and other surfaces to enhance their appearance and performance.

- Flooring: Refurbishing flooring surfaces, such as polishing and recoating, helps maintain their appearance and durability. This is particularly important in high-traffic areas where wear and tear are more pronounced.

- Facades and Exteriors: The exterior surfaces of buildings are exposed to weather and environmental conditions, which can cause damage over time. Refurbishing facades and exterior surfaces helps preserve their appearance and protect against further deterioration.

4. Infrastructure and Public Works

Infrastructure projects, such as roads, bridges, and public facilities, require regular refurbishment to ensure their safety and functionality. Maintaining these surfaces helps extend their service life and supports their continued use.

- Roads and Pavements: Refurbishing roads and pavements involves repairing cracks, resurfacing, and applying protective coatings to extend their lifespan and improve safety for users.

- Bridges and Public Facilities: Structural refurbishment of bridges and public facilities addresses issues such as corrosion, cracking, and surface wear, ensuring these critical assets remain safe and functional.

Choosing the Right Surface Refurbishment Service

When selecting a surface refurbishment service, it’s important to consider several factors to ensure you receive high-quality results and value for your investment.

- Experience and Expertise: Look for a service provider with a proven track record and experience in handling similar refurbishment projects. Their expertise will ensure they can effectively address your specific needs and challenges.

- Quality of Materials and Equipment: The quality of materials and equipment used in refurbishment directly impacts the durability and effectiveness of the results. Choose a provider that uses high-quality, industry-standard materials and advanced equipment.

Customer Reviews and Testimonials: Reading reviews and testimonials from previous clients can provide insights into the provider’s reliability, workmanship, and customer service. Positive feedback and successful case studies are indicators of a reputable service provider.

Questions to Ask Your Service Provider

To make an informed decision, ask potential service providers the following questions:

- What techniques and materials do you recommend for my specific surface refurbishment needs?

- Can you provide a detailed estimate, including labor, materials, and any additional costs?

- What is the expected timeline for completing the refurbishment project?

- Do you offer warranties or guarantees on your workmanship and materials?

- Can you provide references or case studies of similar projects you have completed?

Case Studies and Success Stories

Real-world examples of successful surface refurbishment projects can demonstrate the effectiveness of various techniques and highlight the benefits of professional services. Case studies provide valuable insights into how different approaches have been applied in practice, showcasing the results and client satisfaction.

DIY vs. Professional Surface Refurbishment

Pros and Cons of DIY Refurbishment

DIY surface refurbishment can be a cost-effective option for simple projects. However, it also comes with potential risks and challenges.

- Cost Savings vs. Risks: While DIY refurbishment can save money on labor costs, it may also lead to issues if not executed properly. Common challenges include inadequate preparation, improper application techniques, and the use of subpar materials.

- Tools and Materials: DIY projects require access to appropriate tools and materials, which can be a significant investment. Additionally, achieving a professional-quality finish may be difficult without the right equipment and expertise.

When to Hire a Professional

For complex or large-scale refurbishment projects, hiring a professional is often the best choice.

- Complex Projects: Professional services are equipped to handle intricate and demanding projects, such as those involving specialized surfaces or requiring advanced techniques. They can ensure high-quality results and address any unexpected challenges.

- Expert Knowledge and Equipment: Professionals have the expertise, experience, and access to advanced equipment necessary for effective surface refurbishment. Their skills and knowledge can lead to better outcomes and longer-lasting results.

Maintenance Tips for Refurbished Surfaces

1. Regular Inspection and Monitoring

To maximize the benefits of surface refurbishment, it’s important to regularly inspect and monitor the condition of refurbished surfaces.

- Identifying Early Signs of Wear: Regular inspections help detect early signs of wear, such as minor cracks or peeling coatings, before they develop into more significant issues. Addressing these problems promptly can prevent further damage and extend the life of the surface.

2. Cleaning and Care Guidelines

Proper cleaning and care are essential for maintaining the condition of refurbished surfaces.

- Best Practices: Follow recommended cleaning and maintenance practices specific to the type of surface and coating used. This may include using gentle cleaning agents, avoiding abrasive tools, and adhering to any manufacturer guidelines.

- Scheduling Preventive Refurbishment

Planning and scheduling preventive refurbishment can help maintain surfaces in optimal condition.

- Routine Refurbishment: Regularly scheduled refurbishment helps address minor issues before they become major problems. Establishing a maintenance schedule based on usage and environmental conditions can help ensure surfaces remain in good condition.

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of a refurbished surface?

- The lifespan of a refurbished surface depends on the materials used, the quality of the refurbishment, and the conditions it is exposed to. With proper maintenance, refurbished surfaces can last several years, often comparable to or even exceeding the lifespan of new installations.

2. How often should surface refurbishment be performed?

- The frequency of surface refurbishment varies based on factors such as the type of surface, its usage, and environmental conditions. Generally, surfaces should be inspected regularly, and refurbishment should be scheduled as needed, typically every 3-5 years for high-traffic or exposed surfaces.

3. Can surface refurbishment be done in cold or wet conditions?

- Some refurbishment techniques require specific environmental conditions for optimal results. For example, certain coatings may need dry, warm conditions to cure properly. It’s important to consult with a professional to determine the best approach for refurbishment in varying conditions.

4. Are there eco-friendly options for surface refurbishment?

- Yes, there are several eco-friendly options available, including low-VOC coatings, water-based cleaners, and recyclable materials. Choosing these options can reduce environmental impact and support sustainable practices.

5. How do I choose the right refurbishment service for my project?

- When selecting a refurbishment service, consider factors such as experience, expertise, quality of materials and equipment, and customer reviews. Asking detailed questions and reviewing case studies can also help ensure you choose a reputable provider that meets your needs.

Related Article

Choosing the Right Surface Refurbishment Method for Your Needs

Conclusion

If you’re ready to restore the beauty and functionality of your surfaces, look no further than Epoxy Oilserv Nigeria Limited. Our expert team is dedicated to providing top-notch surface refurbishment services tailored to your needs. Discover more about our offerings and how we can help you achieve outstanding results by visiting Epoxy Oilserv Nigeria Limited. Contact us today to schedule a consultation and get started on your refurbishment project!